Specifications

RACI casing spacers are made of interlocking HDPE segments with no metal bolts or attachments. Engineered with high impact strength and a low coefficient of friction, they guarantee the reliability and success of your underground infrastructure projects.

Engineered for durability and precision, RACI casing spacers provide long-term support for underground piping systems—with published load ratings and corrosion-resistant HDPE that performs where steel falls short.

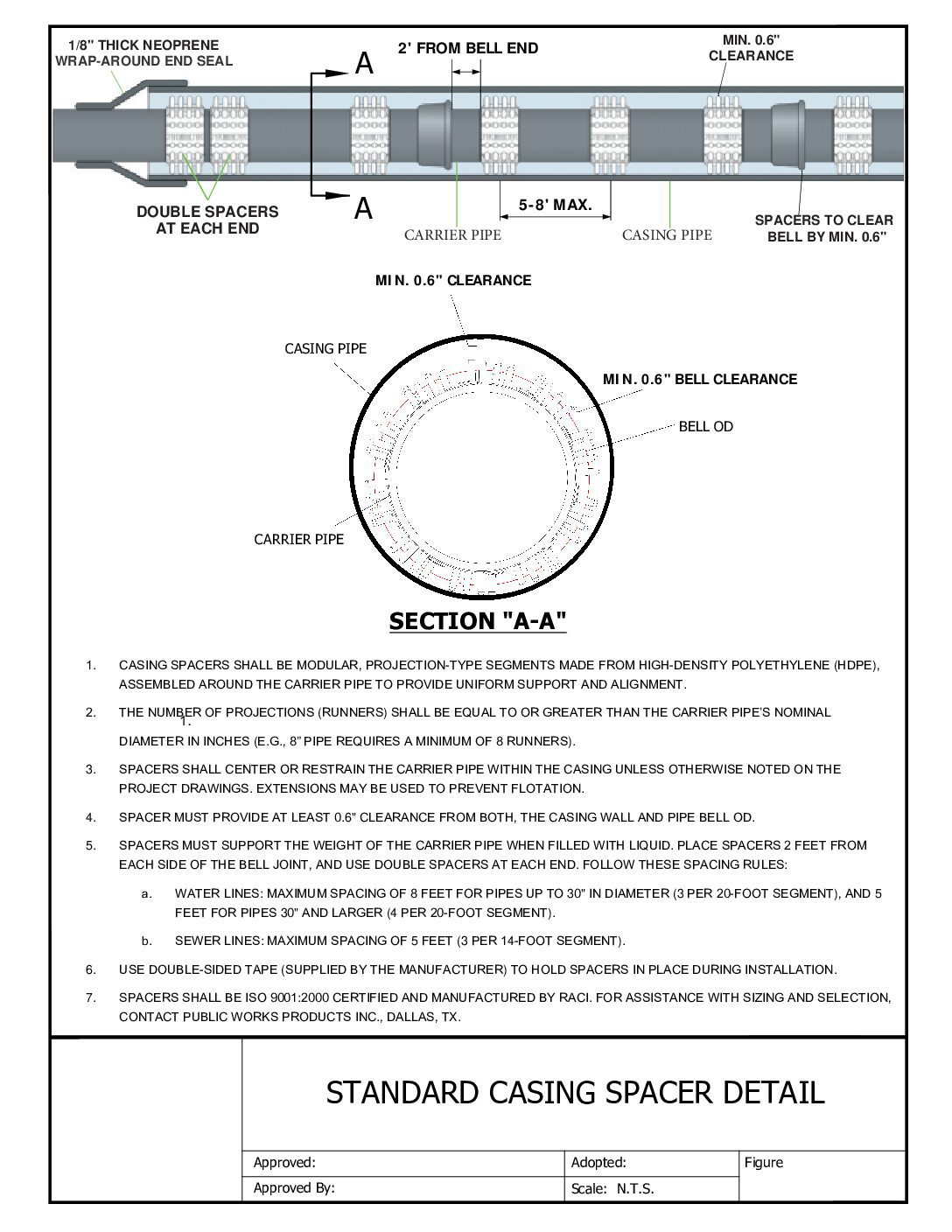

- Casing spacers shall be modular, projection-type segments made from high-density polyethylene (HDPE), assembled around the carrier pipe to provide uniform support and alignment.

- The number of projections (runners) shall be equal to or greater than the carrier pipe’s nominal diameter in inches (e.g., 8” pipe requires a minimum of 8 runners).

- Spacers shall be designed to center or restrain the carrier pipe within the casing unless otherwise noted on the project drawings. Extensions may be used where necessary to maintain alignment or prevent flotation.

- Spacers must provide a minimum clearance of 0.6″ between the spacer outer diameter (OD) and the casing inner diameter (ID), and must also clear the bell end of the pipe by a minimum of 0.6″.

- Spacers should always be able to support the weight of the carrier pipe when filled with liquid. As a general guideline, place spacers 2 feet from each side of the bell joint, use double spacers at each end of the casing, and follow these spacing recommendations:

- Water Lines: Maximum spacing of 8 feet for pipes up to 30″ in diameter (3 per 20-foot segment), and 5 feet for pipes 30″ and larger (4 per 20-foot segment).

- Sewer Lines: Maximum spacing of 5 feet (3 per 14-foot segment).

- Spacers shall be installed using double-sided tape provided by the manufacturer to prevent movement during insertion.

- Spacers shall be ISO 9001:2000 certified and manufactured by RACI. For assistance with sizing and selection, contact Public Works Products Inc., Dallas, TX.